|

Above, you see a screen shot of QuickCAD by AutoDesk. While it is no longer being sold, a very similar program

is AutoCAD LT. A big step up in CAD software is RhinoCAD 3-D. RhinoCAD can do everything 2-D, plus 3-D too.

CAD programs let you draw objects in vectors. Vectors are mathematical expressions that have a point of

origin, a direction, and a length. What these really means to us is that these lines can be easily manipulated, scaled up

or down, and they don't change their relationship relative to each other. In a normal picture, if you zoom in you'll

see that the picture is actually made up of little squares. Zoom in too much and the picture doesn't look like anything. This

isn't the case with a vector drawing. You can zoom in as much as you like because the vectors don't really have a thickness

to them.

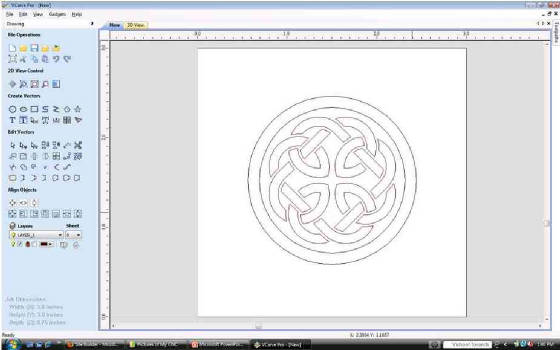

Why do I like CAD so much? Here is why: this is the same drawing imported directly into VCarve Pro. This

is CAM software. With V Carve Pro, I'll be able to put tool path on those vectors. I'll tell the CNC which cutter I am going

to use, how fast it should move, how deep it should go... etc. I can go from just a drawing to an actual part, by going from

CAD to CAM.

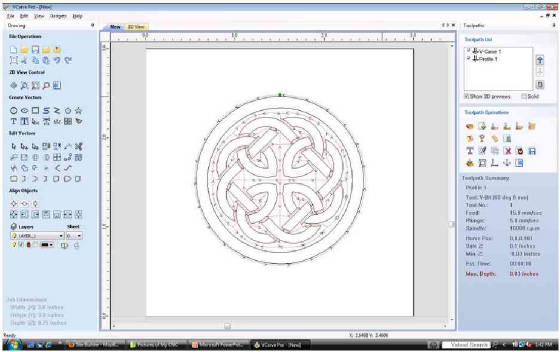

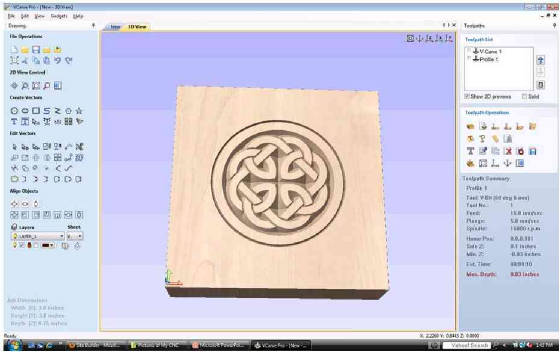

In the screen shot above, you can see the lines that show where the router will cut the wood. If I want

to, I can tell it where to put the cutter down into the wood. I can specify if it should cut the circles clockwise or counter

clockwise. I can control how deep the cutter goes and how fast it goes. A neat thing about VCarve Pro is that you can

simulate the toolpath and show what the final product will look like. This way, you can make adjustments and get everything

just right before the wood chips start to fly.

|