|

I built the 13" x 13" table from Dave's plans at www.solsylva.com Unfortunately, it looks like that website is gone. Dave might be out of business; I can't find him on

the Internet.

Overall, these were some excellent plans. Every part is listed. The instuctions are very clear. It is a pretty inexpensive way

to learn about CNC. The electronics and stepper motors can be used on a bigger table when you are ready to move up.

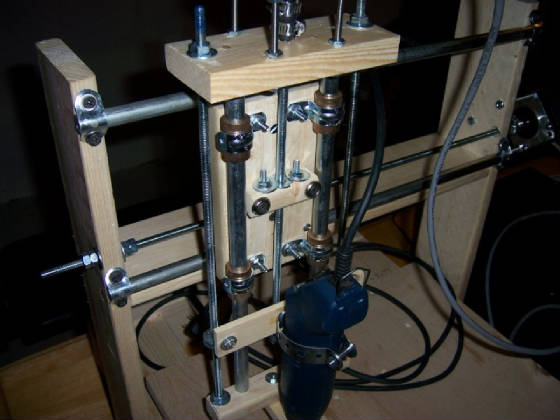

I bought all the parts needed to make this table at either Lowes or Home Depot. You can see that the bronze

bushings act as linear bearings. They are held in place with EMT straps. All thread (1/4 - 20) acts as the lead screws. The

stepper motors turn and that causes the router to move also. For a spindle, I am using an old Ryobi rotary tool but a Dremel

also works nicely, but the RPM is too high and the torque is too low for this tool to be perfect for CNC. Also, a Dremel has

a lot of runout. It isn't a good as CNC spindle. If you need to make bigger things, you'll need a bigger router and

table.

This is just a great little router table. Built right and adjusted correctly, it can be extremely precise.

To give you an idea of how precisely, I've used 0.4mm endmills without breaking them. I've also cut out parts using a 1/8"

router bit with no problem. This table is inexpensive to build and easy to troubleshoot. One disadvantage is that it

can't take a lot of side loading without deflecting. There is flexing along each axis. All this means is that you'll need

to take many light passes with the cutters.

I've used the table I built for about 4 years, only recently replacing it with a K2

CNC table. The only recommendation that I have for improvement would be to put delrin anti-backlash leadnuts in it from

the beginning. The t-nuts specified in the plans work great at first and they are easy to find, but with a lot of use they

will wear out. You'll get lots of backlash and the quality of what you are making will go down. A good source for these delrin

leadnuts is www.dumpsterCNC.com I've got over 500 hours of actual machining time on my little CNC and the leadnuts from dumpsterCNC

just won't wear out. They look as good as when I put them in 3 years ago. If you'd like, you can make your own leadnuts from

delrin (you can find it on ebay).

|